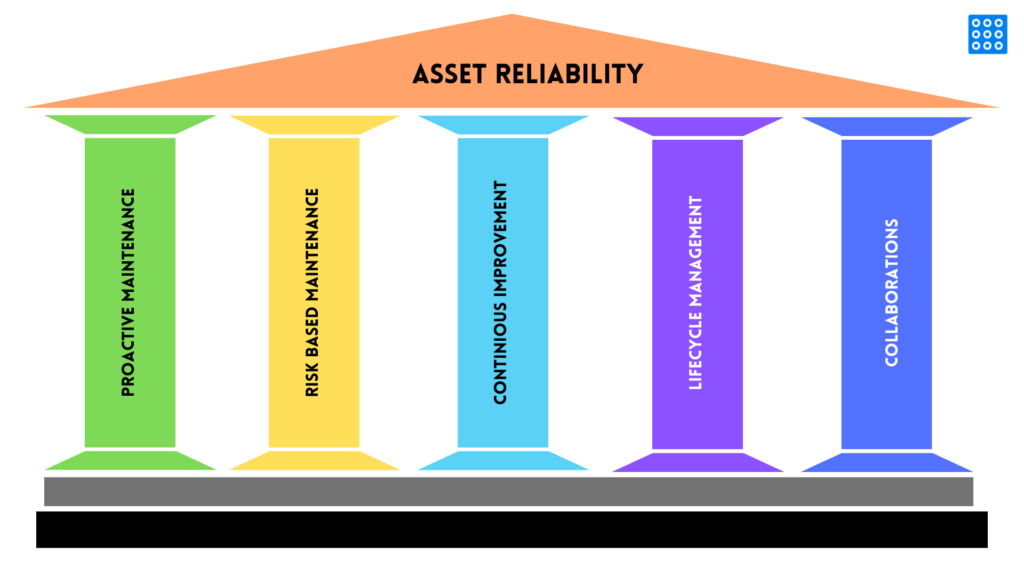

Asset reliability focuses on ensuring assets perform consistently and avoid breakdowns. This involves collecting data on asset health and performance, using it to plan preventive maintenance and identify potential issues early. Techniques like Root Cause Analysis help prevent recurring failures, while performance benchmarking identifies areas for improvement. By managing spare parts inventory, training staff, and continuously improving practices, you can maximise uptime, optimise performance, and get the most out of your assets.

#reliability maintenance engineering #reliability and safety engineering #reliability engineering and system safety #reliability and maintenance engineering

- Defect Elimination Strategies

- Risk Based Inspection (RBI)

- Root Cause Failure Analysis (RCFA)

- Condition-Based Monitoring (CBM) Strategies

- Reliability Centered Maintenance (RCM)

- Reliability, Availability, and Maintainability (RAM) Optimization

- Failure Modes, Effects, and Criticality Analysis (FMECA)

#asset integrity and reliability #reliability and asset management #asset reliability services #system reliability engineering #asset and reliability #reliability centered asset management

Prognoxs leads the industry in offering comprehensive AIMS. These services are specifically designed to guarantee the safe and dependable operation of your assets. Our carefully crafted AIMS programs are aimed at ensuring both safety and efficiency. They integrate key elements such as equipment design, maintenance strategies, inspection protocols, and operational management practices. Prognoxs’ team of multidisciplinary safety management specialists is adept at auditing and enhancing the current safety setups of your asset integrity, thereby ensuring optimal productivity, reliability, and security.

#reliability engineering #asset reliability #asset reliability management #reliable asset management #reliability engineering and asset management #asset management and reliability engineering #asset reliability and maintenance management #asset management and reliability

- Pipeline Integrity Management

- Structural Integrity Management

- Condition Assessment Studies (CAS)

- Corrosion Management Plan (CMP)

- Corrosion Risk Assessment Study (CRAS)

- Safety Integrity Level (SIL)

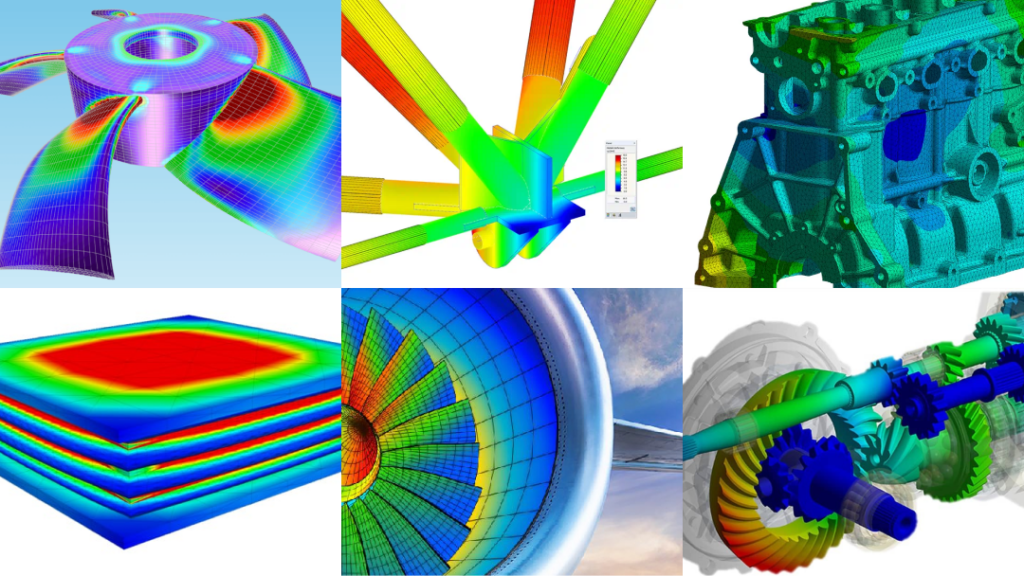

- Engineering Assessment and Design Analysis (FEA)

#maintenance reliability and asset management #reliability engineering services #reliability and system safety #reliability in engineering design